Download

Click here to download this article as a .pdf document.

Introduction – A Shift in Perspective

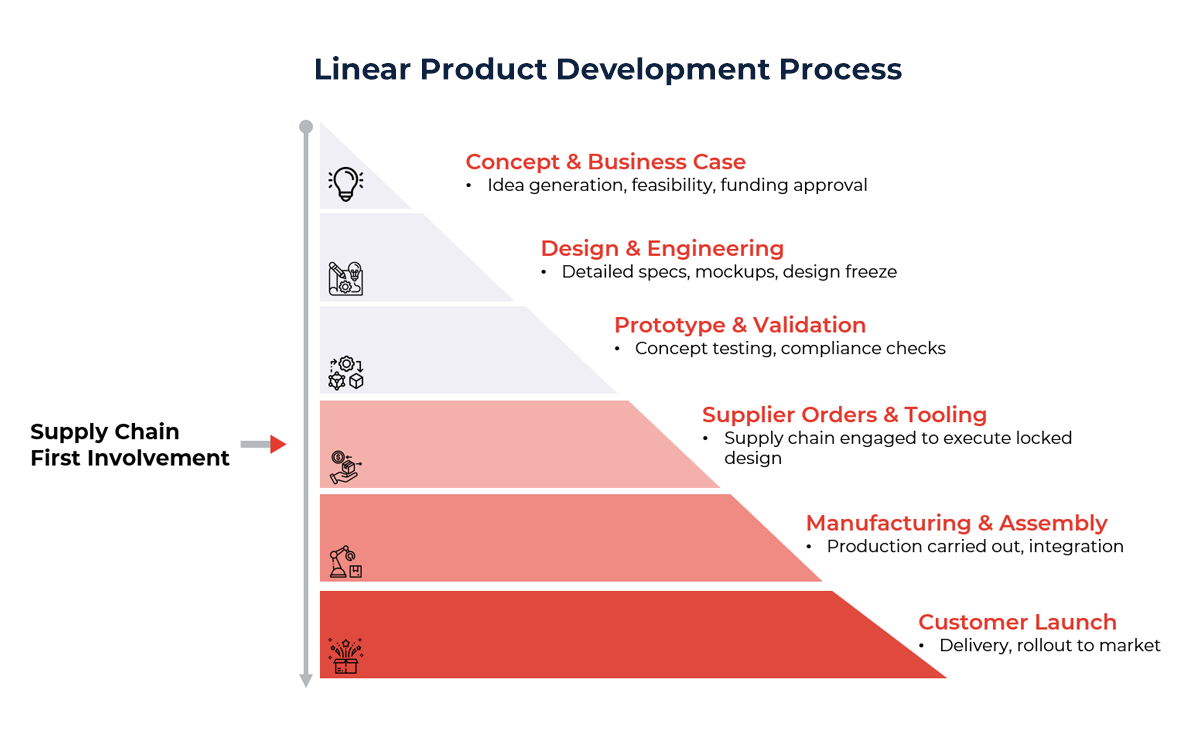

For decades, supply chain was defined by efficiency: cost control, on-time delivery, and smooth execution. Product innovation, by contrast, was owned by R&D, often headquartered in Europe or the U.S. and viewed as the “creative engine” of the company. These two domains operated in sequence: R&D designed, then supply chain executed.

This traditional model is increasingly outdated. Global markets are more volatile, product life cycles are shorter, and customer expectations for speed, sustainability, and customization are higher than ever. Meanwhile, critical know-how in manufacturing processes, materials, and technology often resides with suppliers far from headquarters.

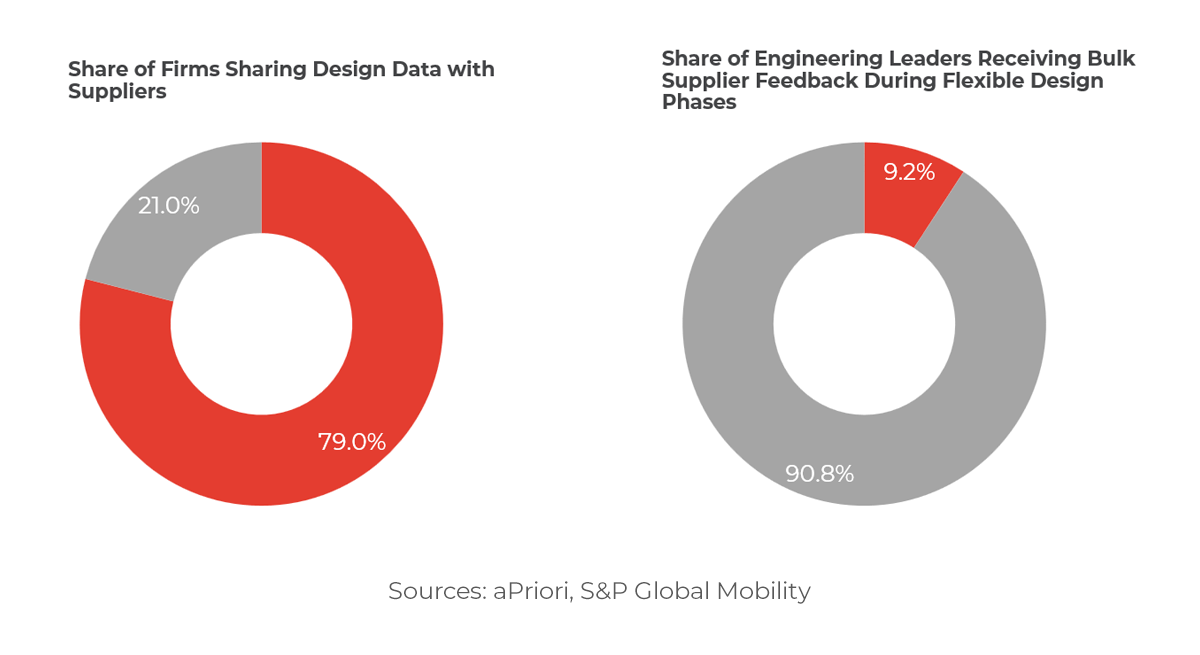

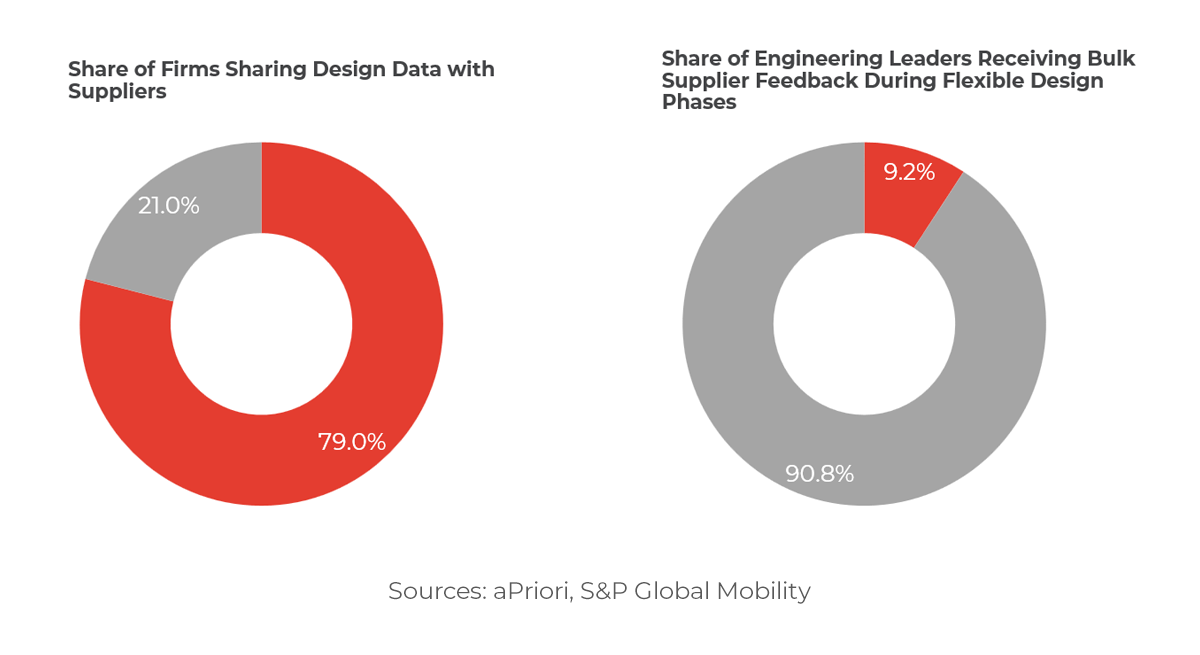

Surveys show companies are beginning to build the digital backbone for better integration: 54% of executives report “high maturity” in internal supply chain data platforms, and 79% of firms in Europe, Japan, and the U.S. have at least started sharing design data with suppliers[1][2]. But “started” is not the same as effective. Most organizations remain at an early stage. In fact, only 9.2% of engineering leaders say they receive the bulk of supplier feedback while designs are still flexible[3].

The result is a dangerous disconnect: slower innovation, higher costs, and fragile designs that fail to scale. The imperative is clear: embed supply chain, including procurement, manufacturing, and key suppliers into product development from day one, shifting from sequential hand-offs to concurrent co-design.

The Challenge – More Than Just Distance

The most visible issue is geographic: R&D hubs in Europe or the U.S. are separated by thousands of kilometers from their supplier bases in China, Vietnam, or Mexico. This creates limited interaction and missed opportunities for collaboration. But the real challenge is much deeper and multi-dimensional:

- Geographic Disconnect – Physical and cultural distance between HQ R&D and suppliers leads to weak collaboration.

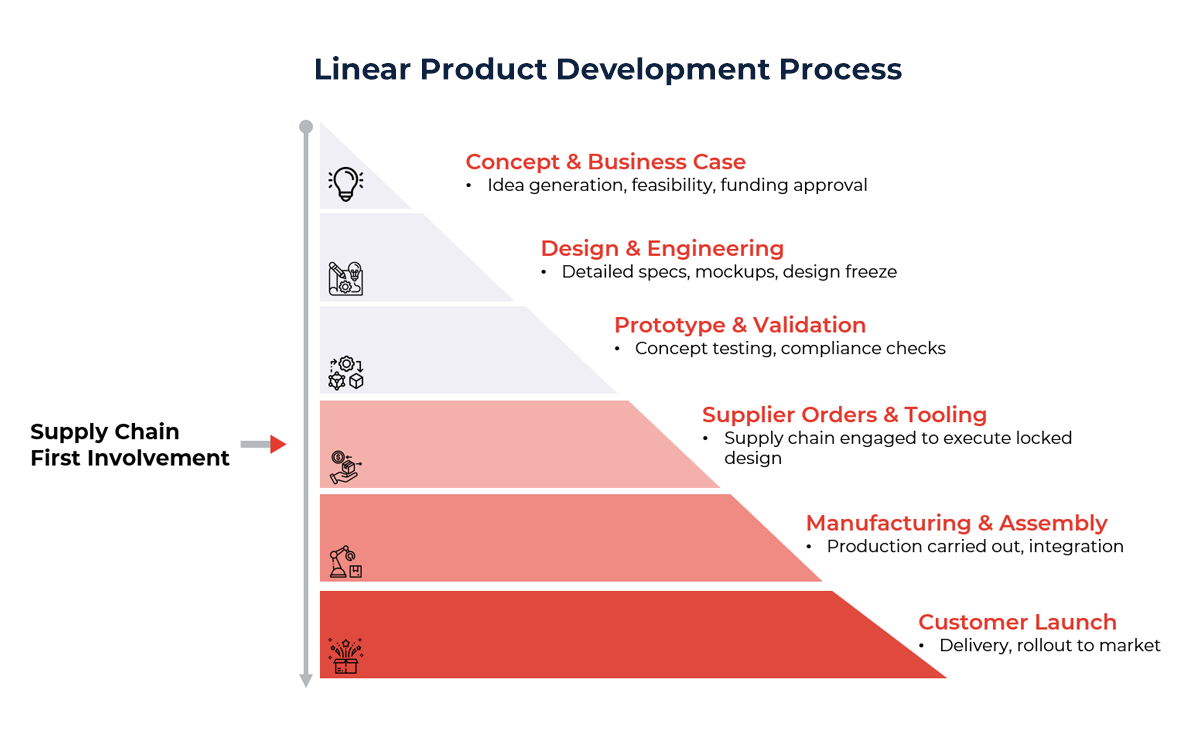

- Process Disconnect – Traditional linear hand-offs (R&D designs → supply chain executes) cause redesign loops and costly delays.

- Capability Disconnect – Supplier expertise in materials or manufacturing is rarely tapped during design.

- Technology Disconnect – Lack of integrated digital platforms prevents real-time sharing of data between R&D and supply chain.

- Strategic Disconnect – Supply chain is often seen as an executor, not as a co-owner of product innovation.

Taken together, these disconnects leave product development fragmented, designs are created in isolation, while supply chain expertise arrives too late to influence outcomes. The result is longer cycles, higher redesign costs, and missed opportunities to leverage supply chain know-how.

Why Supply Chain Matters in New Product Development

To overcome these disconnects, companies must move beyond treating supply chain as an afterthought. Leadership must explicitly recognize it as a co-owner of innovation strategy. When supply chain is engaged early, the benefits go well beyond cost control.

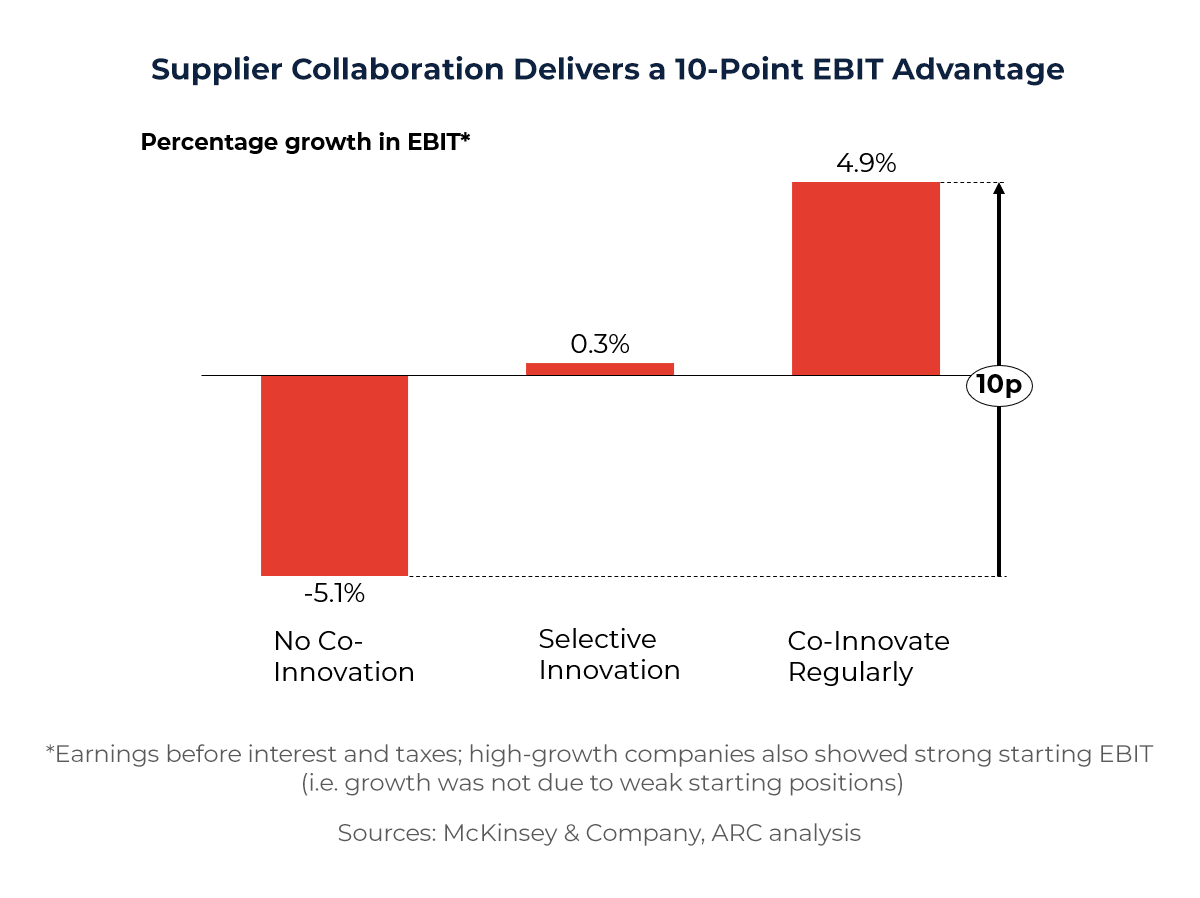

Reframing supply chain as a partner in innovation creates significant value:

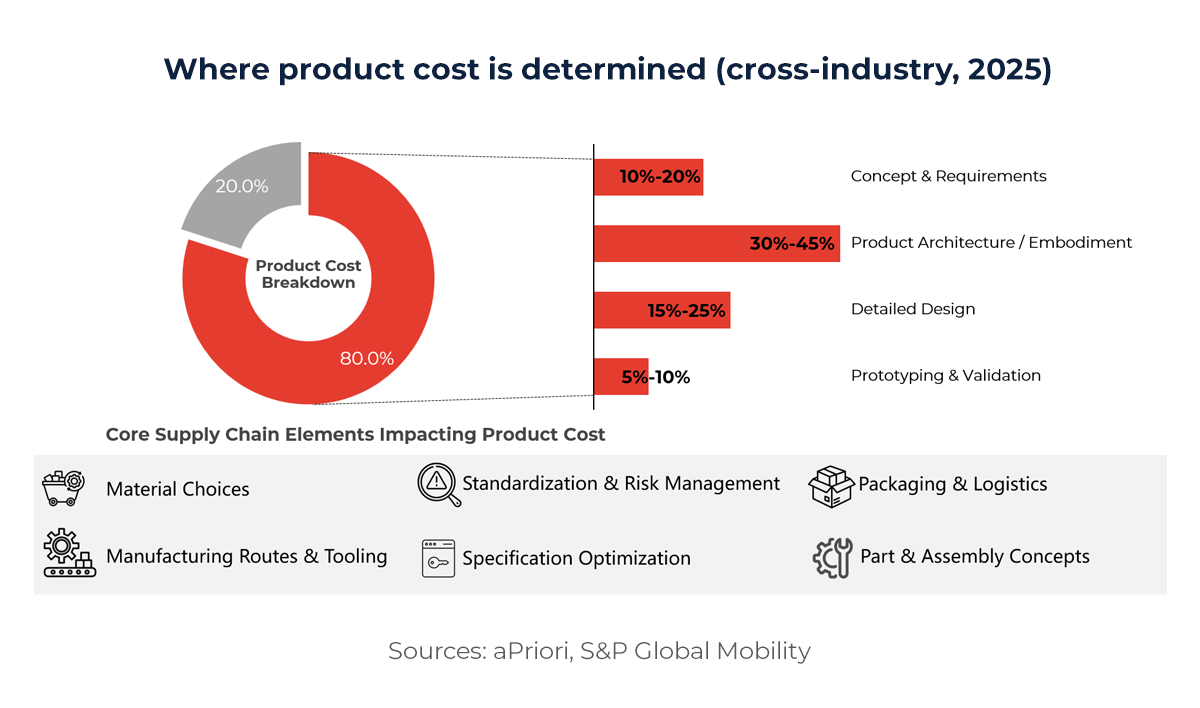

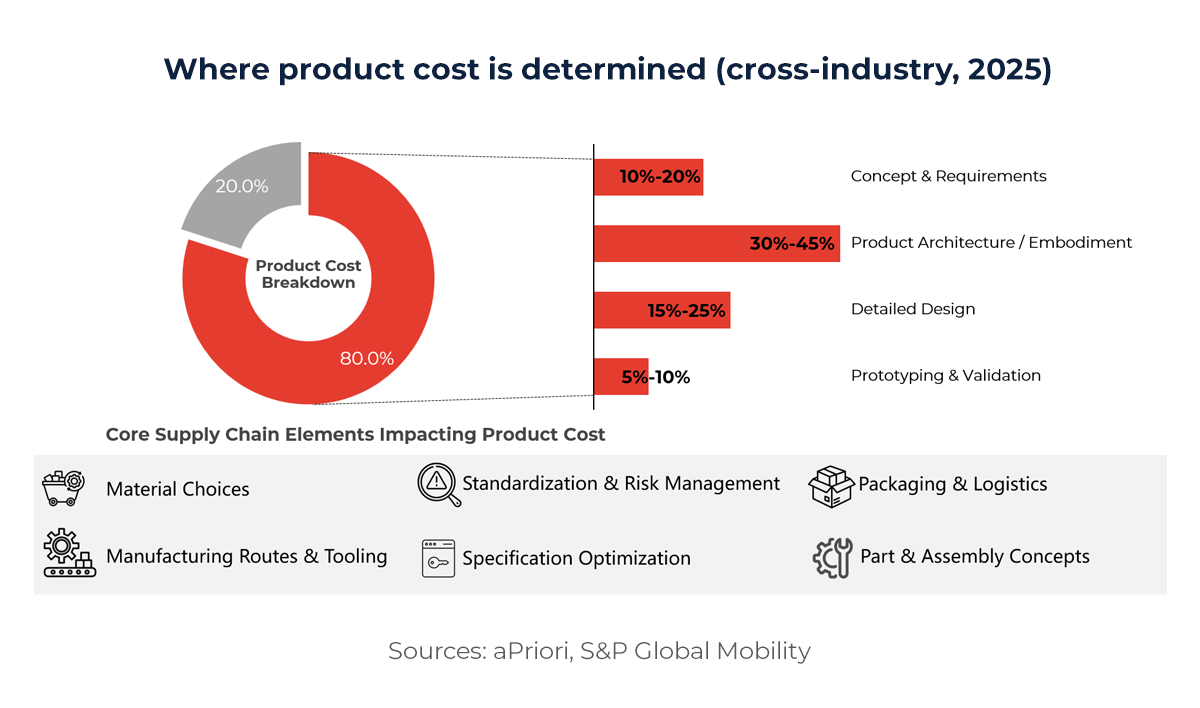

- Design-to-cost and manufacturability – Research shows that up to 80% of lifecycle costs are locked in during the design stage. Supply chain involvement here is decisive

- Lead time and scalability – Supply chain alignment ensures feasibility and accelerates the ramp-up from prototype to mass production.

- Resilience and compliance – Supply chain insights address risks early, from geopolitical exposure to ESG compliance.

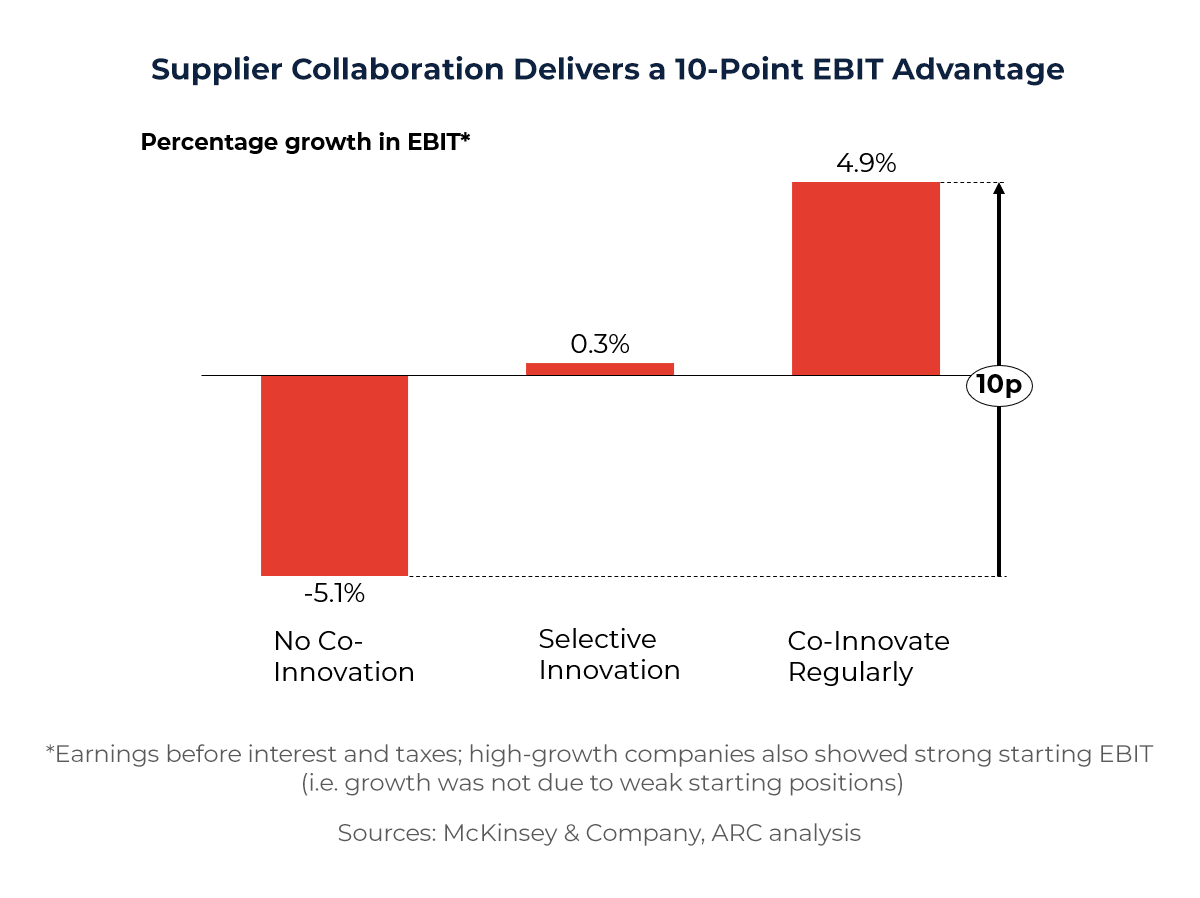

- Supplier innovation – Many OEMs and component suppliers have expertise in new materials and processes that can reshape product performance.

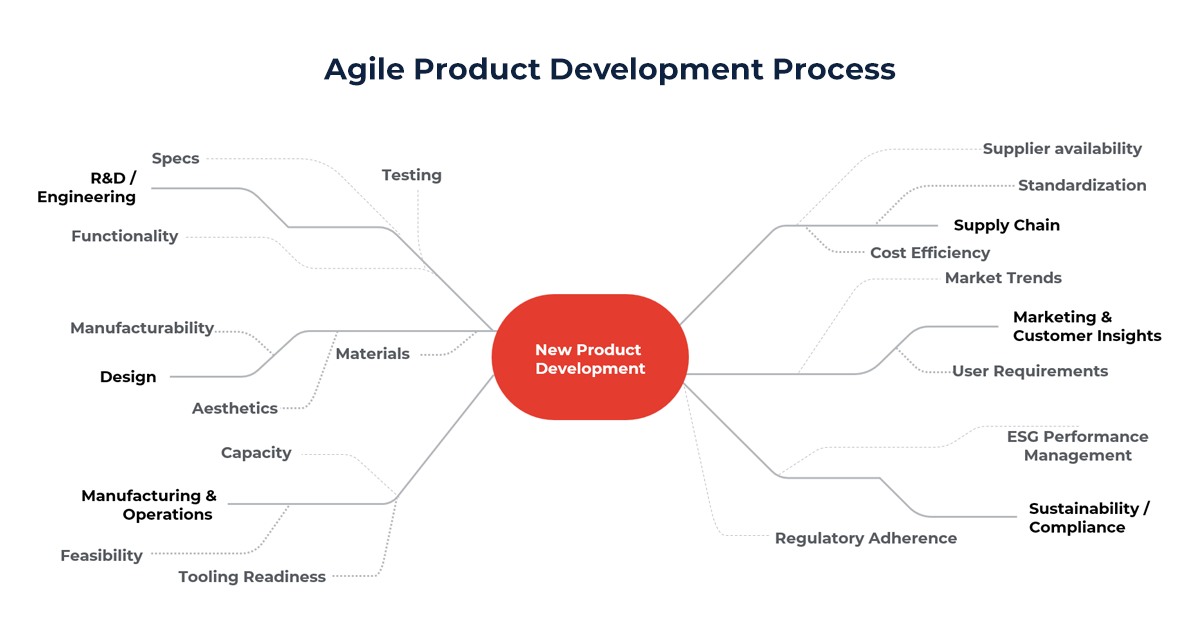

What an Agile Supply Chain in Product Development Looks Like

Recognizing the value of supply chain involvement is only the first step. The real challenge is operationalizing it. Traditional linear hand-offs must be replaced by a development model where R&D, procurement, suppliers, and manufacturing work in parallel, not in sequence.

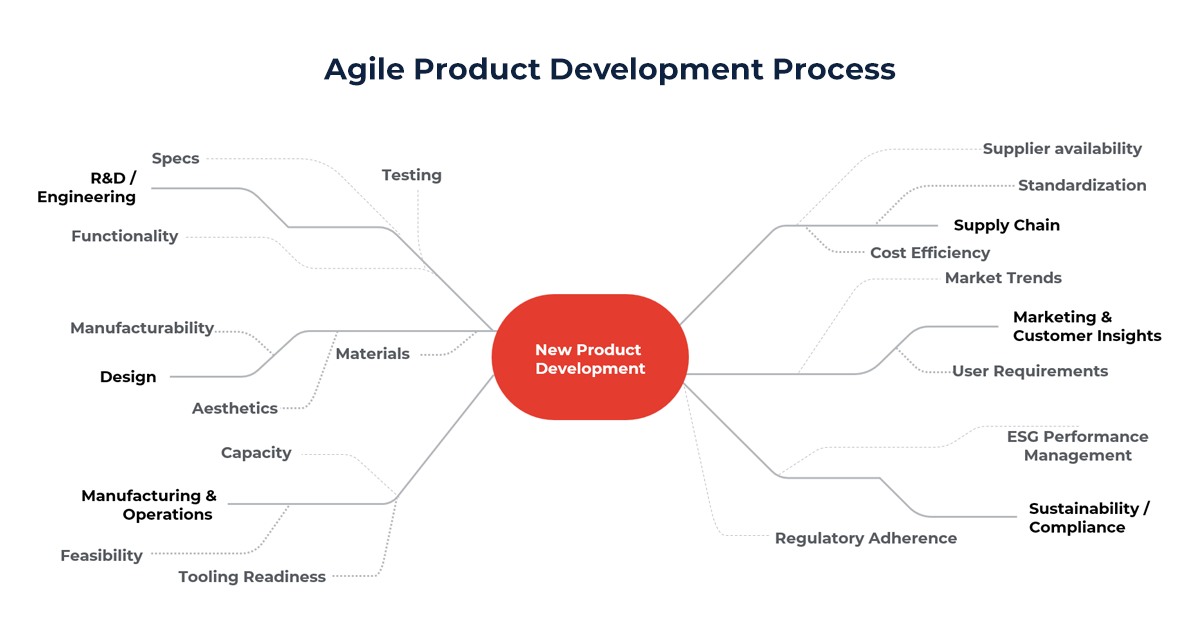

The agile model reimagines supply chain as a true co-creator in the innovation process. Its guiding principles include:

- Cross-functional collaboration – Supply chain specialists embedded in R&D stage gates, not consulted only after design freeze.

- Rapid iteration – Continuous feedback loops between R&D and supply chain shorten cycles and prevent late-stage surprises.

- Flexibility and responsiveness – Agile supply chains can pivot suppliers or materials quickly to adapt to changing market or regulatory conditions.

- Ecosystem mindset – Suppliers are treated as innovation partners, not simply vendors. This is vital in today’s globalized landscape where know-how is distributed across the globe.

Digital Enablers – Making Collaboration Work

Embedding supply chain into product development is only part of the shift. To fully realize its potential, companies need to embed digital into this new way of working. Digital technologies don’t replace collaboration, they amplify it, connecting R&D, procurement, manufacturing, and suppliers in real time and making co-creation faster, more transparent, and more scalable.

Digital technologies provide the tools to make R&D–supply chain collaboration effective at scale:

- Test manufacturability before prototyping with Digital Twins that simulate products and supply chains for resilience and sustainability.

- Gain real-time cost and risk visibility through Advanced Planning and Visibility Systems that enable “design-to-cost” and “design-to-resilience.”

- Collaborate seamlessly across geographies using Cloud Platforms where engineers and suppliers can share CAD files and procurement data instantly.

- Optimize design and sourcing decisions with AI and Advanced Analytics that forecast demand, flag material risks, and suggest improvements.

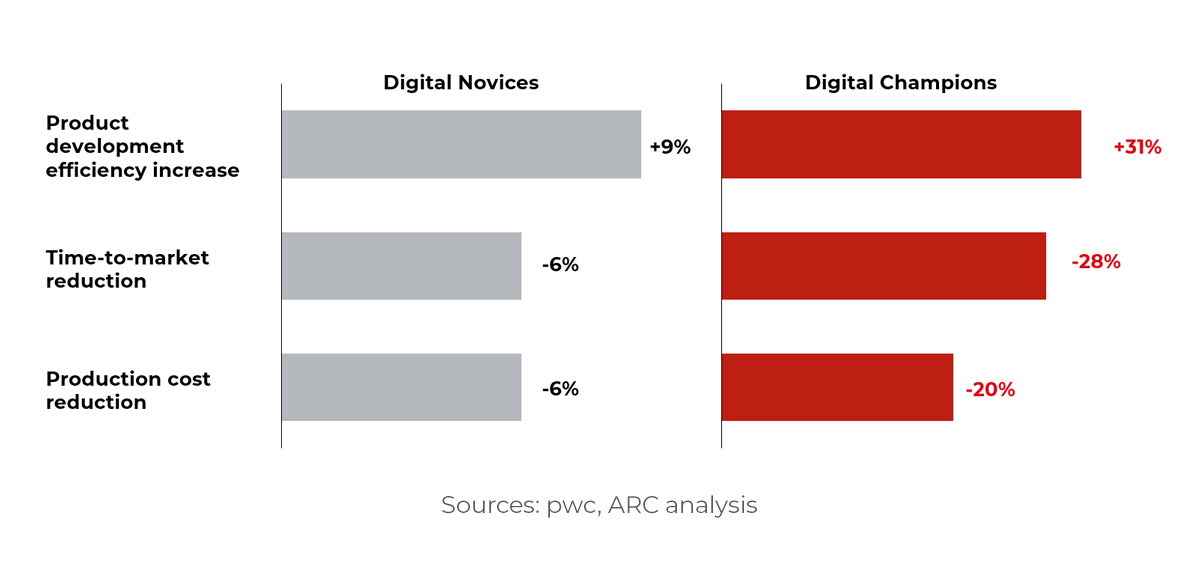

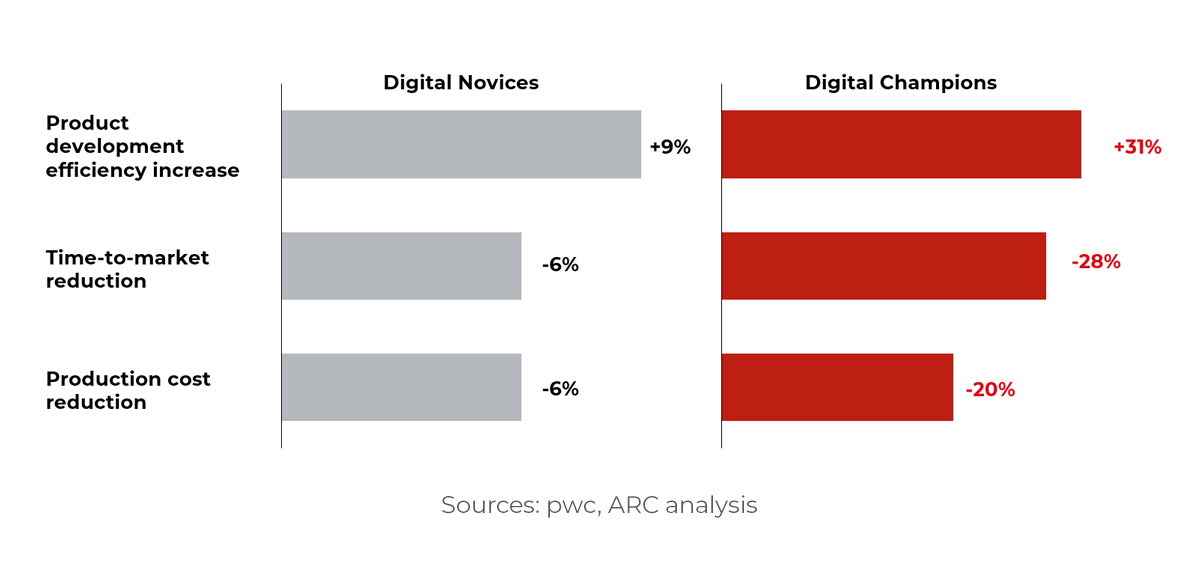

When digital is embedded into product development, the payoff is clear: companies report markedly faster development cycles, stronger cost control, and higher innovation throughput. The data shows significant improvements across efficiency, time-to-market, and product performance, evidence that digitalization amplifies the impact of integrated supply chain collaboration.

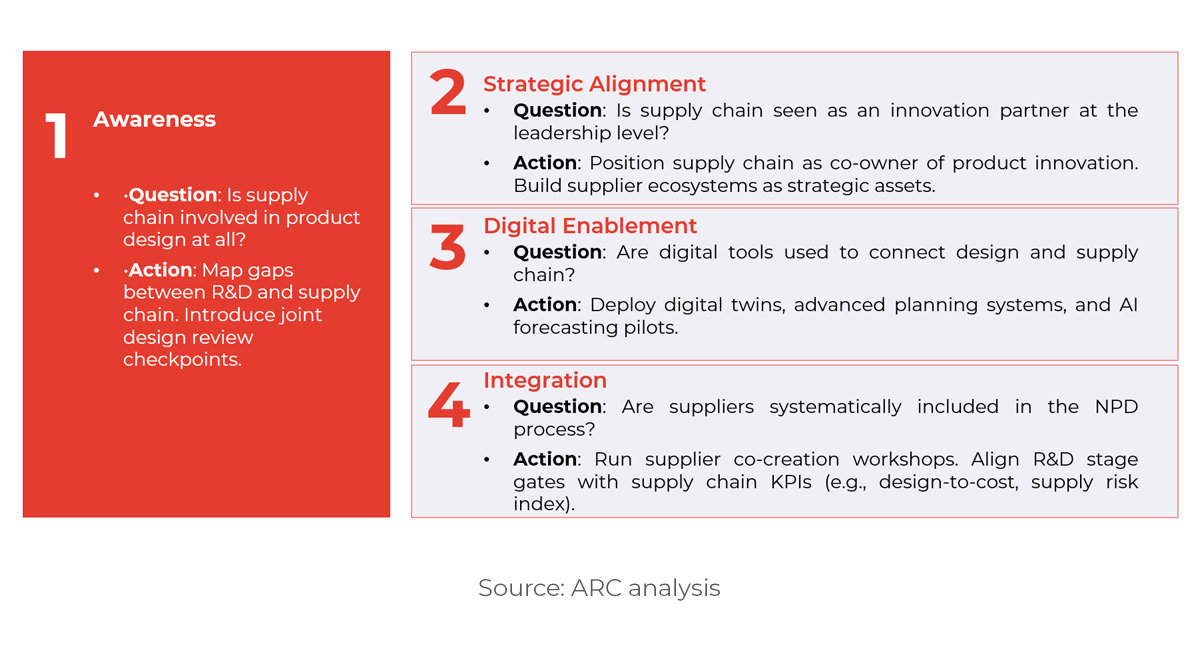

Rethinking Product Development From a Supply Chain Perspective

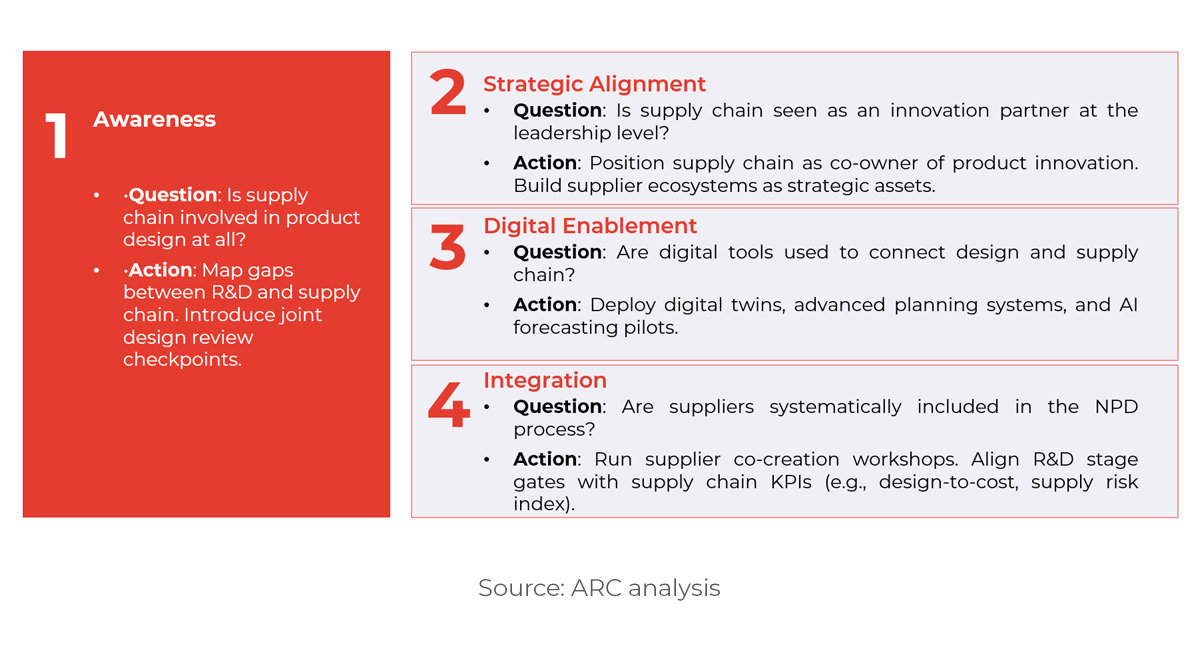

There is no single path to embedding supply chain in product development. Companies sit at different levels of maturity, from those only beginning to involve supply chain in design, to leaders building digitally enabled, integrated ecosystems. To progress, companies must assess their current position, whether at the stage of awareness, strategic alignment, digital enablement, or integration, and identify the practical next steps that will move them forward.

Conclusion – How to Make It Happen

Supply chain is no longer just execution. It is a strategic partner in product innovation — ensuring that new products are cost-effective, scalable, resilient, and aligned with market demands.

The winners will:

- Treat supply chain as a co-owner of innovation.

- Build agile, digitally enabled collaboration models between HQs, suppliers, and OEMs.

- Apply a structured maturity framework to guide their journey step by step.

By rethinking product development from a supply chain perspective, organizations can achieve faster time-to-market, stronger resilience, and more sustainable growth, turning their supply chains into true innovation chains.

Download

Click here to download this article as a .pdf document.

References:

[1] Capgemini Research Institute. (2025, February). New-generation supply chain: Connecting the links to reach common goals. Capgemini.

[2] Aras & Lifecycle Insights. (2023, May). The digital thread: Bringing design and manufacturing together. Aras.

[3] Capgemini Research Institute. (2024, October). The digital thread: Bringing design and manufacturing together. Capgemini.